📖This is the story of Chipblaster, a story we are thrilled to tell you.

The beginning: ChipBLASTER Inc.

It all began in 1994, when ChipBLASTER Inc. was founded in Meadville, Pennsylvania. Since then, ChipBLASTER has focused on designing, manufacturing, and distributing high-quality high pressure coolant systems with the following philosophy:

🚀Create the most technologically advanced and the highest value products

📈Improve products to increase customer’s profits

🤝Maintain strong and long-term relationship with customers and employees.

The evolution: U.S. market leader

Over the past years, ChipBLASTER Inc. gained the finest technical expertise to provide:

🔧Longer tool life

❄️Longer coolant life

🔎Superior chip control

⬆️More part throughput

⏱️Faster cutting speeds

and became the market leader in the U.S. high-pressure coolant industry 🔝

Chipblaster : Tailored solutions

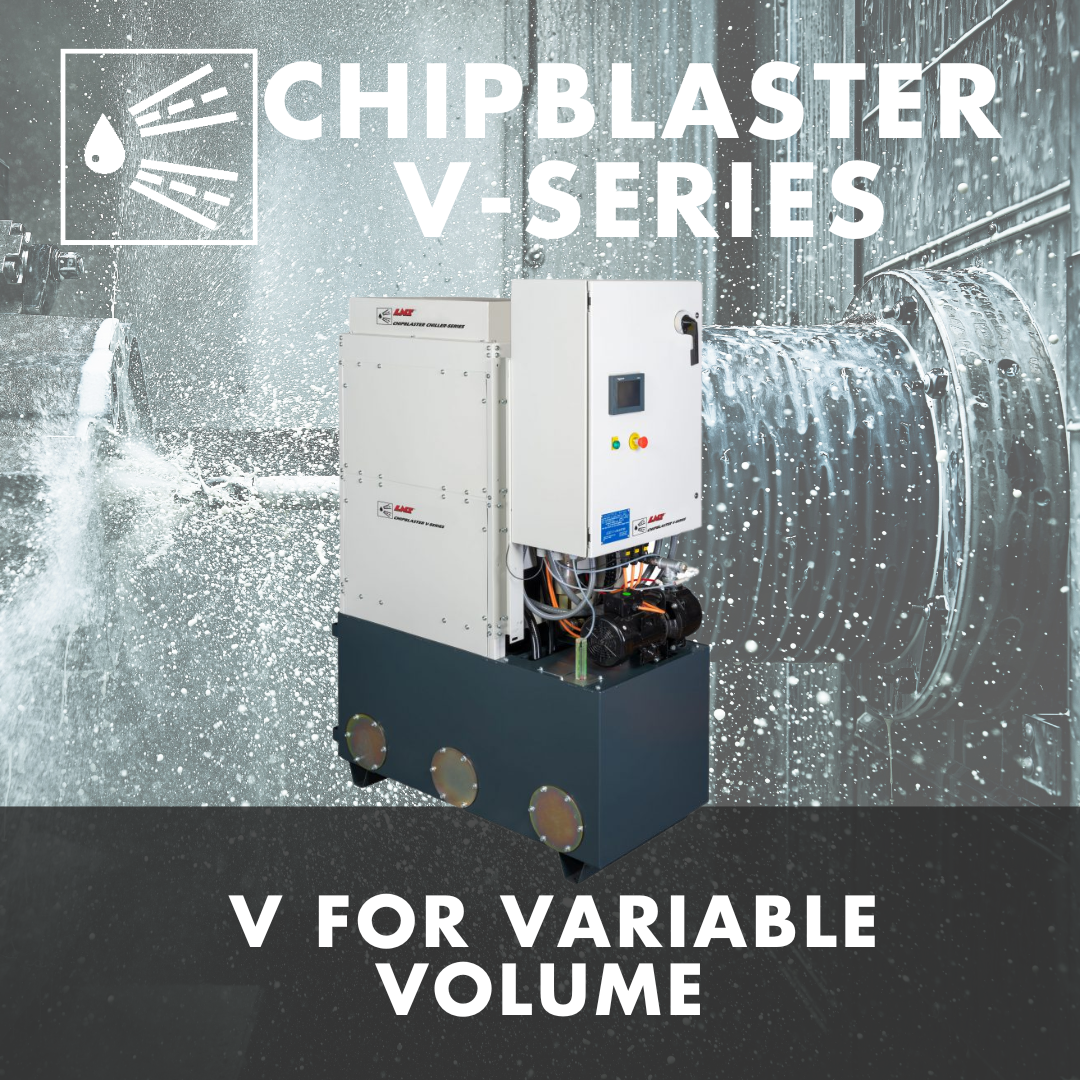

✅The benefits of the Chipblaster product range are clear: Chipblaster systems automatically supply a variable volume of high-pressure coolant to optimize machining performance, tool life, chip removal, machine tool efficiency and energy consumption.

For total control of the machine tool environment, the Coolant Chiller incorporates a circulating pump 🔄, filter alarm and signal circuits 🚨, and ambient temperature monitoring 🌡️.

🌡️ 🔥 ❄️ This system enables machine tools to maintain optimum operating temperature, minimizing thermal drift and the impact of temperature variations. This ensures that the machine tools maintain a maximum degree of accuracy regardless of the production floor environment.

The acquisition: ChipBLASTER Inc. becomes LNS Chipblaster

Back in 2018, the LNS Group acquired ChipBLASTER, Inc. The high-pressure coolant company was a natural fit into the LNS machine tool peripheral product portfolio, leveraging a global sales and service network on a worldwide basis. 🌎 🌍 🌏

This latest acquisition allows LNS to assert itself as a true "one-stop shop" and to offer a complete product portfolio 🔄 that allows machine tools to be equipped with all the necessary peripherals for an efficient 💯 and healthy working environment 🍃

How we made it possible in Europe?

When ChipBLASTER Inc. was acquired by LNS, it was essential to share cultures and know-how. LNS is in constant contact with the North American teams, but not only this. The Group was keen to accompany this change in the form of an international mobility contract with Nicholas Karnes.

Our expatriate, Nicholas Karnes, Nick, a 29-year-old Pennsylvanian, was sent to Switzerland to bridge the two organizations.

After graduating with a Bachelor's degree in Electrical and Computer Engineering Technology, he started at ChipBLASTER Inc. as an Electrical Engineer. The idea of moving Nick to Switzerland came after ChipBLASTER was acquired by the LNS Group. With the opportunity to expand worldwide came the demand for more sales and service support, especially in the European market.

Nick moved to Switzerland in August 2019 and expanded into a more general product support role, including training on the installation of units and how to sell them. Nick also supports Chipblaster units in their specific applications that may require engineering and R&D adjustments.

While the initial project was a 1–2-year assignment to observe the progress of Chipblaster products in the European market, Nick has since signed a contract to stay in Switzerland permanently. Although he misses his family and friends, he is enjoying Switzerland very much.

"The best advice I can give to an expatriate is to just try it and enjoy it. Not many people get the opportunity to have these experiences, to see plenty of new places and to meet so many new people from different cultures. I would never look back and wish I didn’t do it. Of course, sometimes it is difficult being away from friends and family, or being integrated in a new culture, but you have to just push through that and realize there are plenty of advantages in this kind of opportunity. "